Pre engineered buildings have become a common substitute for many uses in modern construction. H beams, which give the building structural strength, are an essential part of the many components used in the construction of these structures.

Let’s look at the function of H beams in peb structures, highlighting their benefits and importance in maintaining the stability, strength, and longevity of PEBs.

H-Beams: What Are They?

Wide flange beams, or H-beams, are beams made of steel that have a cross-section that looks like the letter “H.” These beams are made to support large weights and offer structural stability in a variety of building applications. In the context of pre-engineered buildings, H-beams serve as the fundamental structural components that sustain the building’s weight while ensuring efficiency and stability. The two primary parts of H beams are flanges and webs. They are typically utilized where huge loads must be supported and where the ground is unstable, like on bridges.

The Role of H-Beams in Pre-Engineered Buildings

Pre-engineered buildings (PEBs) are factory-built structures assembled on-site. The integration of H-beams into the design of these buildings is vital in ensuring that they can withstand various loads and external forces. Let’s delve into the primary roles that H-beams play in PEBs:

1. Providing the ability to bear load and solidity.

In pre-engineered buildings, the main purpose of H-beams is to give the framework rigidity and stability. The weight of the roof, walls, and other components are spread uniformly with the use of H-beams, which are horizontal load-bearing elements. Their design resists bending and deformation under high load conditions due to its wide flanges and vertical web. Due to this, H-beams are ideal for high-span structures that need superior support.

2. Stabilization of vertical loads

H-beams have a significant role in supporting vertical loads in addition to horizontal loads. H beams distribute the building’s weight to the base by functioning as a vertical column in many pre-engineered construction designs. To guarantee that the structure is secure and stable under strain from both the vertical and horizontal directions, these beams are thoughtfully positioned at regular intervals.

3. Distribution of Load and Foundation

The foundation of a pre-engineered structure is crucial for its durability over time. H-beams are integrated into concrete foundations or secured with base plates to adequately distribute the loads to the base. This guarantees that the building’s weight is spread evenly across the foundation, which helps avoid settling or shifts in the structure as time goes on. The design of the foundation, which includes the H beams, significantly influences the long-term stability of the building.

4. Resistance to Sudden Seismic Activities and Wind

Pre-engineered buildings are often designed to withstand external forces, including wind loads and seismic activity. H-beams contribute to the durability of PEBs against the forces by making the structural framework of the building. Cross-bracing and other steel components are often connected to the H-beams to provide lateral stability, preventing shaking or shifting that could occur due to strong winds or earthquakes.

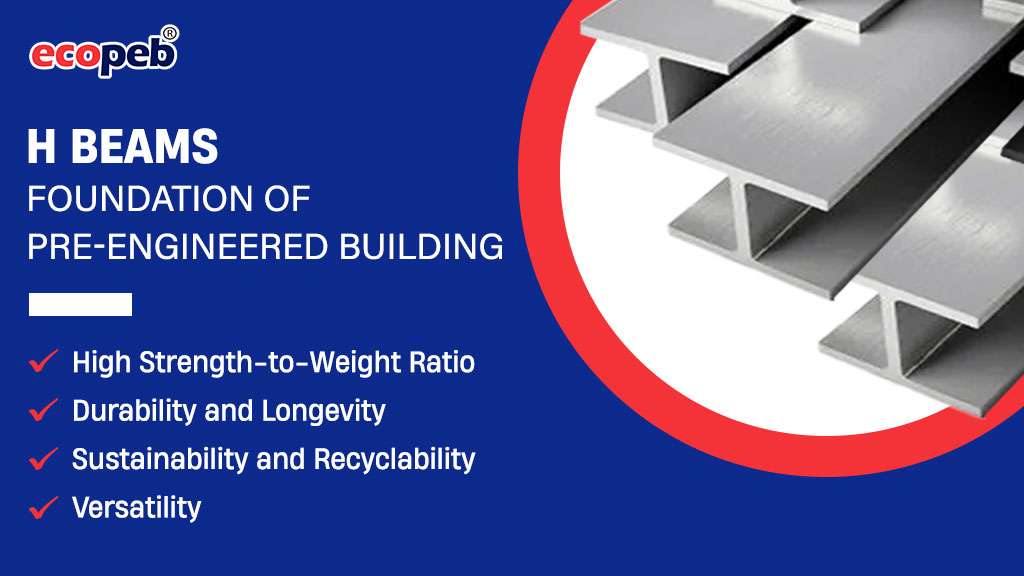

Key Benefits of Using H-Beams in Pre-Engineered Buildings

The incorporation of H-beams into pre-engineered building designs offers several advantages that make them a perfect choice in modern construction. Below are the key advantages of using H-beams:

- High Strength-to-Weight Ratio

One of the most significant advantages of H-beams is their high strength-to-weight ratio. Steel has an excellent strength-to-weight ratio, which allows H-beams to support essential loads while being relatively lightweight. This characteristic makes them ideal for large-span PEBs, where reduction of weight is important without compromizing the strength of the building.

- Cost-Effective in Construction

While the initial material cost of steel is higher than other building materials, the use of H-beams in pre-engineered buildings results in being cost-effective in the long term. The high strength of steel allows for less use of material, which in turn lowers the overall cost of construction. Also, the prefabrication process, which is done off site in PEBs, which includes H-beams, reduces labor and construction time, leading to cost savings.

- Speed and Efficiency in Construction

H-beams are manufactured off-site, meaning they are produced with exact specifications and dimensions in a factory environment with high accuracy. Once completed, they are transported to the construction site for installation. This method significantly shortens the duration of on-site construction, facilitating quicker assembly of the entire pre-engineered building. Reduced construction times contribute to lower labor expenses and faster project deliverables, making PEBs an ideal selection for both builders and property owners.

- Durability and Longevity

Steel provides significant flexibility in design and customization. In contrast to conventional materials such as wood or brick, steel can be shaped and formed to fulfill particular design specifications, granting architects and builders greater creative latitude. Steel constructions can effortlessly accommodate large spans and open layouts, making them ideal for structures that need expansive, unobstructed areas, like warehouses or manufacturing plants.

- Sustainability and Recyclability

H-beams contribute to the sustainability of preengineered buildings. Steel is a 100% recyclable material, which means that H-beams can be reused and repurposed at the end of their life cycle.It can be melted down and redesigned into another structure. This reduces the construction waste and minimizes the environmental impact of the construction. As sustainability becomes an increasingly important concern in the construction industry, H-beams offer an eco-friendly alternative to other materials.

How H-Beams Enhance the Performance of Pre-Engineered Buildings

The incorporation of H-beams into pre-engineered building designs increases the overall performance and durability of the structure. H-beams provide strength, stability, and flexibility, ensuring that the building can withstand various forces such as wind, seismic activity, and heavy loads. Moreover, their lightweight nature and cost-efficiency make them ideal for large-scale industrial, commercial, and recreational buildings.

- Superior Durability and Safety: Our H-Beams are perfect for heavy-duty applications since they are made with the highest quality components to provide the utmost rigidity and durability.

- Quality Engineering: Our H-Beams remain excellent, waste-free, and project-efficient due to their accurate design.

- Versatility: Suits a wide range of uses, including warehouse shipbuilding, bridge construction, and industrial construction.

- Sustainable Solutions: In keeping with our commitment to sustainability, we utilize sustainable manufacturing methods to make sure that our H-Beams have less of an environmental impact.

As the foundation of pre-engineered buildings, H-beams provide the structural support required to ensure durability, strength, and stability. H-beams are an important component in modern construction due to the ability to withstand heavy loads and preserve the affordability, quicker construction timeframes, and sustainability of the whole building. By offering a high ratio of strength to weight, H beams have become the go-to choice for the buildings.